What Are Twist Nails Used For

Types of Nails – Explanation on the Different Blazon of Nail and What They are Used For

Learn all virtually the unlike types of nails and how each type should be used. Also find out the different parts of a nail and what nails are mostly made from and how to choose the right smash for the job using our handy DIY guide.

Using nails is an constructive way of fixing or joining pieces of softwood timber and other similar materials together. Hardwoods can be difficult to join with nails as they tend to bend under the affect of the hammer due to the density of the timber.

Below is a range of nails that can be used depending on the type of forest and the nature of the piece of work to exist attempted.

What are Nails?

This may sound like a pretty empty-headed question to ask as most people, regardless of whether you are involved in structure or any course of DIY, near people will have encountered a nail at some signal in their lives but in that location are some that haven't.

For the uninitiated, traditionally, nails were the "go to" solution for fixing a range of materials together, hanging objects on walls and trees etc. and they engagement all the manner back to Egyptian times, over 3000 years.

In terms of how they work, once hammered into a surface friction takes over and holds the nail inside the material. This procedure is fabricated even more effective if a given smash features barbs, grooves, a twisted shank or shaft as information technology's known (the main trunk pf the blast) as this dramatically increases grip.

Over the years their design hasn't changed a great bargain merely many different types of nail have been developed for specific jobs where standard nails don't quite cutting the mustard.

Sticking with tradition, nails were typically hammered in to a surface using a standard hand held hammer. The user would life the hammer and strike the head of the hammer on the head of the boom driving it down into the surface of the object you are working on. For more information on hand held hammers encounter our projection here.

Today the hand held hammer has been somewhat done away with by the more mod smash gun. These come in electric corded or cordless and too compressor fed (pneumatic) or gas canister powered versions. Near mutual types of nails such as round wire, staples etc. can be used with smash guns.

Due to the time it takes to knock a nail in with a hammer, the nail gun has been a revolutions for tradesmen, assuasive them to piece of work much more chop-chop and efficiently.

Standard cordless electric compressed air blast gun by Ryobi

When it comes to nailing yous have to select the correct nail for the task equally not all nails are suitable for all jobs. Additionally you accept to take note of the timber you are using. Today's mod timber is much weaker than older timber and using the wrong smash will just split the timber and ruin it.

This is too the instance if you use an incorrect sized boom, too long or as well wide and then can easily cause splits and shakes and totally spoil a finish.

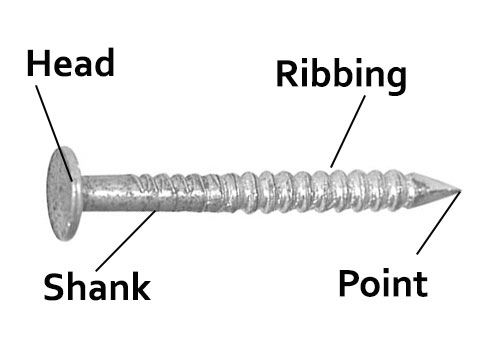

What are the Different Parts of a Nail?

There is essentially 3 parts to a nail; the head, the shaft ro shank and the indicate. The head is used to hit the boom into the material to are working with the, the shaft/shank forms the trunk of the smash and the point is at the finish and allows the nail to be driven into the given material more easily.

- The Head: Blast heads are either big and round ensuring skillful contact with a hammer or small and thin, often the same size as the shank and this allows them to be knocked beneath the surface and filled and hidden

- Shaft or Shank: Generally about nail shanks are smooth and permit them to travel hands through virtually materials, however they tin also be splined, ribbed or spiralled and these features grip into a timber surface holding the blast firmly in once knocked down

- The Point: as this suggests the opposing end of the boom from the head is cut to a fine, sharp point which allows it to penetrate the material you're working with. Generally longer points reduce the adventure of timber splitting whereas shorter blunter points tin occationally cause splitting

The different parts of a smash

What are Nails Made From?

Nails are mostly made of steel but every bit nosotros all know steel is susceptible to moisture and will rust over time, so where nails are to exist used outside or indeed with pressure-treated timber (as the treatmnet causes corrosion) they need to be treated with a protective coating.

Here are the most common materials and finishes used for nails:

- Bright Nails: These are the most common type of nail the name bright referrs to untreated steel and due to this should merely always exist used indoors

- Zinc-Plated Nails: Nails that are coated with a zinc coating are resistant to corrosion and expect silver, sometimes gold in advent, still the coatings are generally quite thin so don't stand upwardly to much

- Galvanized Nails: These types of nails feature a much thicker coating of zinc that the in a higher place type and due to this tin exist used outdoors and with timber that's been pressure treated

- Black Phosphate Nails: These types of nail are normally dark grey or black in appearance and are mainly used for fixing plasterboard. The phosphate coating helps protect the nail and prevent it rusting and too helps plaster and paint to bond to it

- Brass, Bronze and Nickel: These types of nail are generally used in indoor applications, normally for fixing upholstery to furniture and the similar

- Copper: As copper copes extremely well with h2o and wet and does non degrade, copper nails and tacks are mostly used for roofing applications

What are the Different Types of Nails?

There are many, many different types of nail bachelor today, some for full general use with timber and some just to be used for specific jobs. Here follows a listing of some of the near mutual types of smash available today.

Round Wire Nail

This is used for full general fixing piece of work and due to this is the most commonly used blazon of nail today. It is not attractive in shape or when hammered into a piece of timber but they are stiff and provide a decent fixing.

One substantial downside of these nails is that they can separate wood when hammered in position, especially if the wood is of low quality.

Round Wire Nail

Brads or Nail Gun Nails

These are generally used in nail guns and are fired into a given piece of timber using compressed air. They come on a strip that allows then to be loaded into a nail gun.

Generally they come in two different types, starting time fix and second fix, to accommodate the different types of boom gun, and once fired in by the gun, their heads sit below surface level for a smooth cease.

They are used extensively used across all areas of construction, with commencement prepare being larger and more course for heavier job, and second ready being finer for more than fragile work.

On the whole they are comparable to the circular wire blast.

Brads

Turbo Zip Nails

Hammer in fixings which concur similar a screw. In one case inserted, the barbs that feature on the sides of the fixing seize with teeth in to the surrounding fabric belongings information technology firmly in place.

These fixings can exist used both internally and externally for any types of timber and provide a adept and solid fixing that is difficult to strength apart.

These fixings can also exist used for fixing timber to masonry, but y'all have to drill a pilot hole start.

Turbo zip nails

Cutting or Clasp Blast

These types of nails are used for generally fixing timber to soft masonry. Due to their "wedge" shape they provide an excellent strong fixing and are hard to remove once hammered in.

Cut nails are quite large in size so aren't as well suited to delicate applications, merely at that place is a finer version bachelor chosen a floor brad that is designed for floor boards down.

Cut or squeeze nail

Oval Wire Nail

Used extensively across many areas of carpentry for fixing a variety of objects and surfaces, these nails are typically quite long nail and care must exist taken when it is hammered into the wood every bit that can easily bend.

Due to their rather thin nature they are unlikely to split the woods when hammered in (unlike circular wire nails) and once knocked downwardly their smaller oval heads can be knocked beneath the surface for a clean stop.

Oval wire blast

Masonry Nails

These types of nail provide a decent fixing for joining timber and other similar objects to masonry, although they are a adequately lightweight fixing so for heavy objects bolts or screws should be used.

Normally made of hardened zinc they can exist easily hammered into standard physical and like masonry and their zinc makeup ensures they don't rust.

A good example of their use is when fixing rug strips to a solid physical floor.

Masonry nails

lost Head Nail

This type of nail is ideal if it is necessary to hide the caput of the nail once it has been knocked in. A dial tin exist used to knock the head further in if needed where it can be filled over to be totally hidden.

lost head nail

Galvanized Felt Nails

This nail is generally used for fixing covering felt to sheds, outbuildings and other external structures. Information technology features a large head that non only makes information technology easy to strike only once it's been knocked in the big apartment head helps to seal the hole and prevent water ingress.

In pretty much all cases felt nails are galvanized so that they don't rust. They are likewise sometimes known equally "clout" nails.

Galvanised felt nails

Panel Pin

These types of nail are generally quite small and thin and used for fairly fragile and light jobs. Once very common use is for fixing the rear panels on to flat pack furniture such as drawers and wardrobes, but for added forcefulness glue should also be used.

Console pin

Copper Disc Rivet or Tingle

Although they don't look much like a nail, disc rivets are very like to felt nails but in this case are used to set up covering slates to a surface, particularly at the base of operations of tiles. Virtually commonly used for cement fibre slates.

Copper disc rivet or tingle

Tack (upholstery tack)

These are like in a style to cut or squeeze nails in that they are athwart in shape, but this time they feature a flat head. In nigh instances they are used for fixing textile materials to forest for example, fixing upholstery to furniture.

One thing to be aware of is they are quite small-scale and very abrupt and so make sure you don't drop any!

Tack

Square Twist Nail

Sheradised (zinc coated by heating), these nails do in fact feature a square shaft or shank as it's known that is then twisted when hot and and then cut to a point. In terms of use, they are ordinarily used for external cladding and/or felting applications.

Their twisted shaft acts a bit like a screw. As it's hammered in information technology twists creating a stronger concord than a standard directly shaft smash.

Square twist nail

Stainless Steel Slate Hooks

These handy hooks are used for keeping the lesser of slipped slates in place when replacing them. The bent stop is hammer into the roof and so the slate is slipped into the hook end to hold it in identify.

As they are made from stainless steel this prevents them from rusting abroad when exposed to the elements.

Stainless steel slate hooks

Sprig

Again very like in looks cut or clasp nails in that they are angular in shape, they don't feature a head as they are primarily used for holding panes of glass in windows before window putty is applied.

Again they are quite small in size and very sharp so don't misplace any.

Sprig

Cone Head Bulldoze Nail With Spat Washer or Bound Head Blast

As you lot can run into, the shaft of this nail is twisted and when knocked in acts as a screw producing more grip and hold.

By and large used in roofing and used for property down roofing sheets on a roof they are used in conjunction with "spat" washers that keep fixing holes watertight by preventing water ingress.

Cone head drive spiral with washer

Annular Blast

The shaft of this blazon of nail is ribbed and the teeth or barbs aid to hold it in place firmly. As it provides a much more solid fixing than a standard nail information technology is used for fixing plywood and other materials, mostly on floors to terminate movement in joists and help prevent creaking.

Every bit they grip much more than firmly than a standard nail they are also much trickier to remove!

Annular nail

Plasterboard Nails

As the name suggests these nails are used for fixing plasterboard to surfaces, mainly timber studwork and joists. They are merely really used every bit a cheap culling to plasterboard screws but they are no where most equally expert or provide as good a fixing.

They are made of galvanized steel to preclude rusting when fixing in place.

Plasterboard nails

Hardboard Pin

Every bit y'all would await from the proper name, this nail is mainly used for fixing hardboard in identify. Once knocked in the diamond shaped caput is hidden then is ideal when a smooth finish is needed.

Hardboard pin

Staples

Staples or fencing staples as they are also known come in both zinc and galvanized construction as they are mainly used externally for fixing wire and chainlink fencing to contend posts.

They can be hammered in with a standard mitt held hammer or using a fencing stapler (similar a blast gun but for staples).

Staple

Corrugated Fastener

Can be hammered in using a hand held hammer or can besides be used with a nail gun, the corrugated fastener is mainly used for reinforcing wooden frames and joints, particularly mitre joints as it provides additional strength and rigidity to the joint.

They are used with the corrugations facing downwardly with the bottom border beingness precipitous they are hammered downwardly across the joint. Equally this isn't a particularly attractive cease tis is mainly used with rougher carpentry.

Corrugated fastener

Upholstery Pin

Normally finished in bronze or contumely with a 10mm bore caput, they are available in a range of decorative finishes. They're main apply is for pinning upholstery and textile to timber such as when making chairs and other similar objects.

Upholstery pivot

Copper Clout Nail

In terms of appearance they look similar a cantankerous between a felt boom and round wire boom, these nails are primarily used for fixing roofing slates in identify. Every bit they are made of copper they don't rust or corrode.

Copper clout blast

Plastic Headed Nail

The plastic headed nail is mainly used in conjunction with UPVC cladding and UPVC facia boards and are generally used for fixing said objects in place.

The plastic heads are available in white, dark-brown and black to suite the diverse different colours of UPVC bachelor. The coloured heads help to hide the fixing and brand it await less obvious.

Plastic headed nail

Leap Head Nail

The principal use for this type of smash is for fixing sheet materials downward to a structure. A practiced example of this is fixing corrugated plastic, steel or cement fibre covering sheets downwardly.

As with cone caput drive nails the shaft is twisted as once knocked in information technology acts like a screw holding the object much more than firmly than a standard directly shaft smash.

The large domed head helps to keep hole waterproof and they tin can be used along with spat washers for farther water proofing. It besides helps to spread the load of the downward pressure

Spring head nail

Today there is a huge range of unlike nails available to cover the huge range of jobs they can be used for, then ensure you lot use the correct blazon of boom for the job you lot are doing.

Source: https://www.diydoctor.org.uk/projects/typesofnail.htm

Posted by: knightwoust1984.blogspot.com

0 Response to "What Are Twist Nails Used For"

Post a Comment